Our history is full of many important milestones that shaped who we are today. Allow us to take you on a journey that began with the founding of Emmericher Maschinenfabrik. It shows how the drive and pioneering spirit of our three founding fathers grew into a global company that has evolved into the market and technology leader over four generations.

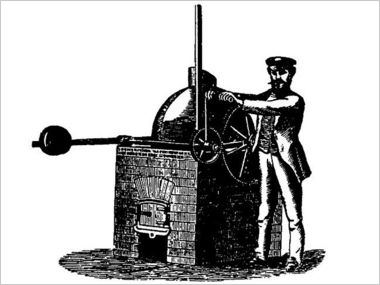

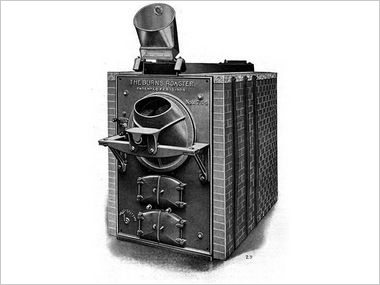

Jabez Burns already sells hundreds of roasters due to increased coffee consumption.

Burns invents the self-emptying coffee roaster, which revolutionizes the coffee roasting industry.

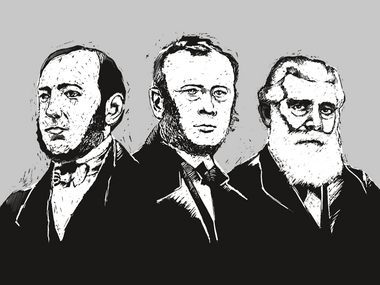

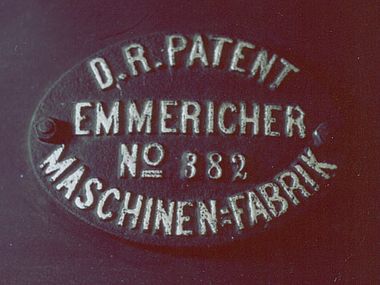

Diligence, a passion for engineering, a pioneering spirit and a love of coffee – these were the driving forces that motivated Alex van Gülpen, Johann Heinrich Lensing and Theodor von Gimborn to found Emmericher Maschinenfabrik und Eisengießerei in 1868.

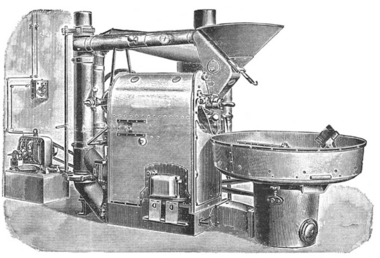

The ambitious goal of the newly founded company was to bring outstanding coffee in reproducible quality and in large quantities to market – using innovative roasting machines that stand the test of time, even at an industrial scale.

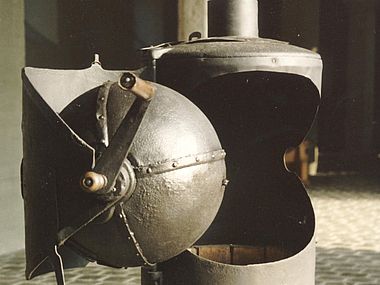

Through their combined expertise, van Gülpen and von Gimborn manufacture the ‘Emmerich Spherical Roaster’, thus beginning a new age of coffee production.

With the granting of a patent for the Kaffeeschnellröster (‘rapid coffee roaster’), a new era of innovation begins. This patent was critical to the revolutionary development of the drum roaster. This basic principle of a drum that rotates along a horizontal axis still remains the most common method of slow-roasting coffee in use today.

The first roaster to carry the ‘PROBAT’ name is manufactured at the Emmerich Machine Factory.

The city of Emmerich is completely destroyed during World War II. The Emmerich Machine Factory also falls victim to the devastating attacks.

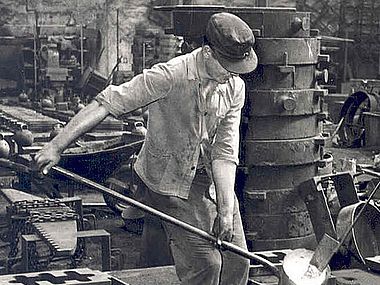

At the Emmerich Machine Factory, the first new cast is poured in the foundry’s newly rebuilt production halls.

This marks the beginning of a new era ...

Probat work expands from Germany to the North American market

Ten years after rebuilding, the Emmerich Machine Factory changes its name,

and Probat-Werke (Probat Factories) is born.

Probat and Burns begin integrating thermal afterburners with roasters in response to local environmental codes.

Probat manufactures the first tangential roaster with the model name ‘Jupiter’. The effectiveness and flexibility of the tangential roasting method still remains unparalleled to this day. The wide range of different roasting times possible and the roaster’s rugged design make it a one-of-a-kind all-rounder.

Patented and unlike anything else in the world –

centrifugal roasting technology from Probat means flexible coffee production with unparalleled results in the medium roasting range.

With its rotating movement along a vertical axis and the combination of roasting bowl and laminar seal ring, the ‘Saturn’ blends the beans in a particularly homogeneous and gentle manner while roasting.

Probat and Burns companies merge and now have the largest market share in North America.

The evolution of the Jupiter series is the first to utilise hybrid technology. Here, we combine all the benefits of Jupiter systems in a tangential roaster. Thanks to its low energy demand, this roaster is environmentally friendly and yet still highly effective.

The new research and development centre in Emmerich opens up a new world of possibility. Here customers can experience coffee in all its facets and details.

In the adjacent laboratory, we analyse the results of roasting using a wide variety of different methods.

Probat Burns opens new training lab to offer hands-on training and coffee roasting education at its USA (or NA) headquarters.

Customized control solutions from Probat optimise all processes, making production planning more flexible and machine utilisation more efficient. As a result, our customers enjoy absolute process and production reliability for even more precise coffee production.

We are celebrating our anniversary year with a variety of different events. As the market leader for innovative roasting solutions, we look back with pride on a long tradition. At the same time, we continue to look ahead and are already focusing on the topics of the future.

The new progressive PROBAT factory in Emmerich mirrors the customers' constantly increasing quality demands on products and services, thus setting an international benchmark in the company's core markets.

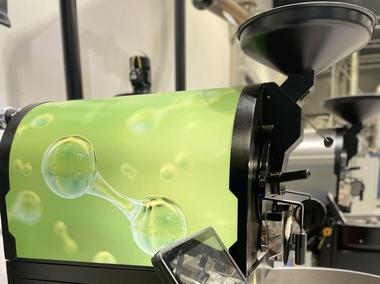

PROBAT introduces the first hydrogen-powered shop roaster.

The use of green hydrogen is milestone for the future of coffee roasting. It is CO2-neutral because it is made using clean electricity from renewable energy technologies by electrolyzing water, separating the hydrogen atom within it from its molecular twin oxygen. An important step for decarbonizing the coffee industry.